E7P Features

- Quick, simple assembly

- A and B quadrature TTL outputs

- Fits shaft diameters from 0.118 in. (3mm) to 0.394 in. (10mm)

- Frequency response DC to 30 kHz

- 180 to 720 cycles per rev (CPR)

- 720 to 2,880 quadrature states per rev.

- Accepts .020 in. axial shaft play

- Single-ended or differential output option

- 5 V supply

The E7P is no longer available for purchase.

The E7P is no longer available for purchase, and has been replaced by our recently released E8T. The E8T is a redesigned, enhanced version of the E7P, and is already available for purchase.

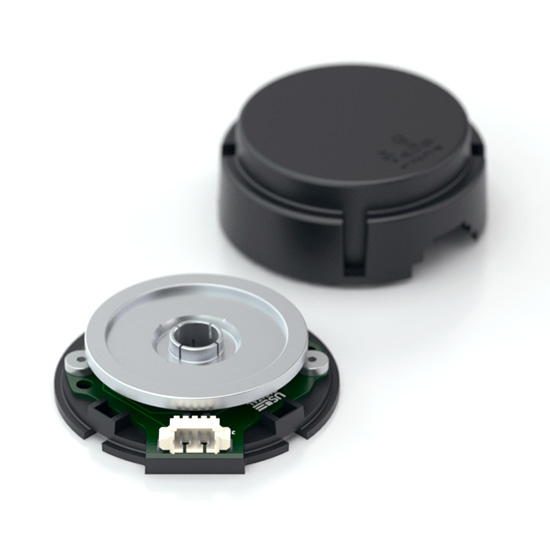

E7P Product Description

The E7P quick assembly optical incremental kit encoder is designed for high volume, low cost, mid-resolution OEM motion control applications. The E7P was designed as a big brother to the E4P encoder and offers higher resolutions, a wider range of shaft diameters, and mounts to additional bolt circles. The E7P uses a 5V supply and offers two TTL quadrature outputs. A single-chip reflective encoder module incorporates an LED, monolithic detector, and molded lenses. The phased array technology accepts far wider mechanical tolerance and misalignment than traditional aperture type encoders.

Two screws secure the base using one of the three-bolt circles. The precision-machined aluminum reflective encoder disk pushes on by hand using a spacing tool to securely grip the shaft while eliminating set screws (patent pending). The cover snaps on to complete the assembly in seconds.

When mounting holes are not available, a centering tool and stick-on version are available. The T-option specifies a base with a transfer adhesive pre-applied. The backing is peeled off, and the base is slid down the shaft guided by the centering tool.

The single-ended output version has a 4-pin connector and is designed to drive cables up to six feet long.

The differential output version has a 6-pin connector and is designed for driving longer cable lengths and maximizes noise immunity. The internal 26C31 differential line driver can source and sink 20 mA at TTL levels. The recommended receiver is industry standard 26C32. Maximum noise immunity is achieved when the differential receiver is terminated with a 150 Ω resistor in series with a .0047 μF capacitor placed across each differential pair. The capacitor conserves power. Otherwise, power consumption would increase by approximately 20 mA per pair or 40 mA for 2 pairs.

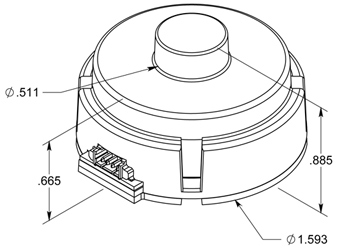

Mechanical Drawings

Specifications

ENVIRONMENTAL

| PARAMETER | VALUE | UNITS |

|---|---|---|

| Vibration (5Hz to 2kHz) | 20 | G |

| Max. Relative Humidity | 90 | % |

| Storage Temperature | -40 to 100 | C |

| Operating Temperature | -20 to 100 | C |

| Electrostatic Discharge, IEC 61000-4-2 Single-ended (S-option) Differential (D-option) |

± 3 ± 2 |

kV |

MECHANICAL

| PARAMETER | VALUE | UNITS |

|---|---|---|

| Max. Shaft Axial Play | ± .020 | in. |

| Max. Off-axis Mounting Tolerance | ± .010 | in. |

| Max. Acceleration | 250000 | rad/sec² |

| Maximum RPM (1) e.x. CPR = 720, max. rpm = 5000 e.x. CPR = 180, max. rpm = 20000 |

minimum value of (3600000/CPR) and (60000) |

rpm |

| Codewheel Moment of Inertia | 7.03 x 10-5 | oz-in-s2 |

| Required Shaft Length With D-Cover option With C-Cover option With E-Cover option With H-Cover option |

0.355 to 0.587 0.355 to 0.430 0.355 to 0.836 >=0.355 |

in. in. in. in. |

| Mounting Screw Torque | 2-3 | in-lbs |

| Technical Bulletin TB1001 - Shaft and Bore Tolerances | Download | |

(1) 60000 rpm is the maximum rpm due to mechanical considerations. The maximum rpm due to the module's 30kHz maximum count frequency is (3600000/CPR).

SINGLE-ENDED ELECTRICAL

| SPECIFICATIONS | MIN. | TYP. | MAX. | UNITS | NOTES |

|---|---|---|---|---|---|

| Supply Voltage | 4.5 | 5.0 | 5.5 | V | |

| Supply Current | 21 | 27 | mA | no load | |

| Low-level Output | 0.4 | V | IOL = 6 mA | ||

| High-level Output | 2.4 | V | IOH = -1 mA | ||

| Rise Time | 500 | ns | CL = 25 pF, RL = 2.7 kΩ | ||

| Fall Time | 100 | ns |

DIFFERENTIAL ELECTRICAL

| SPECIFICATIONS | MIN. | TYP. | MAX. | UNITS | NOTES |

|---|---|---|---|---|---|

| Supply Voltage | 4.5 | 5.0 | 5.5 | V | |

| Supply Current | 23 | 30 | mA | ||

| Low-level Output | 0.2 | 0.4 | V | IOL = 20mA max. | |

| High-level Output | 2.4 | 3.4 | V | IOH = -20mA max. | |

| Differential Output Rise/Fall Time | 15 | ns |

PHASE RELATIONSHIP

| PARAMETER | TYP. | MAX. | UNITS |

|---|---|---|---|

| Symmetry, S | 180 ± 16 | 180 ± 75 | electrical degrees |

| Quadrature Delay, Q | 90 ± 10 | 90 ± 60 | electrical degrees |

(1) A leads B for clockwise shaft rotation, and B leads A for counterclockwise rotation viewed from the cover/label side of the encoder.

(2) Typical values represent the encoder performance at typical mounting alignment, whereas the maximum values represent the encoder performance across the range of recommended mounting tolerance.

PIN-OUTS

| 4-PIN SINGLE-ENDED (1) | 6-PIN DIFFERENTIAL (2) | ||

|---|---|---|---|

| Pin | Description | Pin | Description |

| 1 | +5VDC power | 1 | Ground |

| 2 | A channel | 2 | A channel |

| 3 | Ground | 3 | A- channel |

| 4 | B channel | 4 | +5VDC power |

| 5 | B channel | ||

| 6 | B- channel | ||

(1) 4-pin single-ended mating connector is CON-MIC4

(2) 6-pin differential mating connector is CON-MIC6

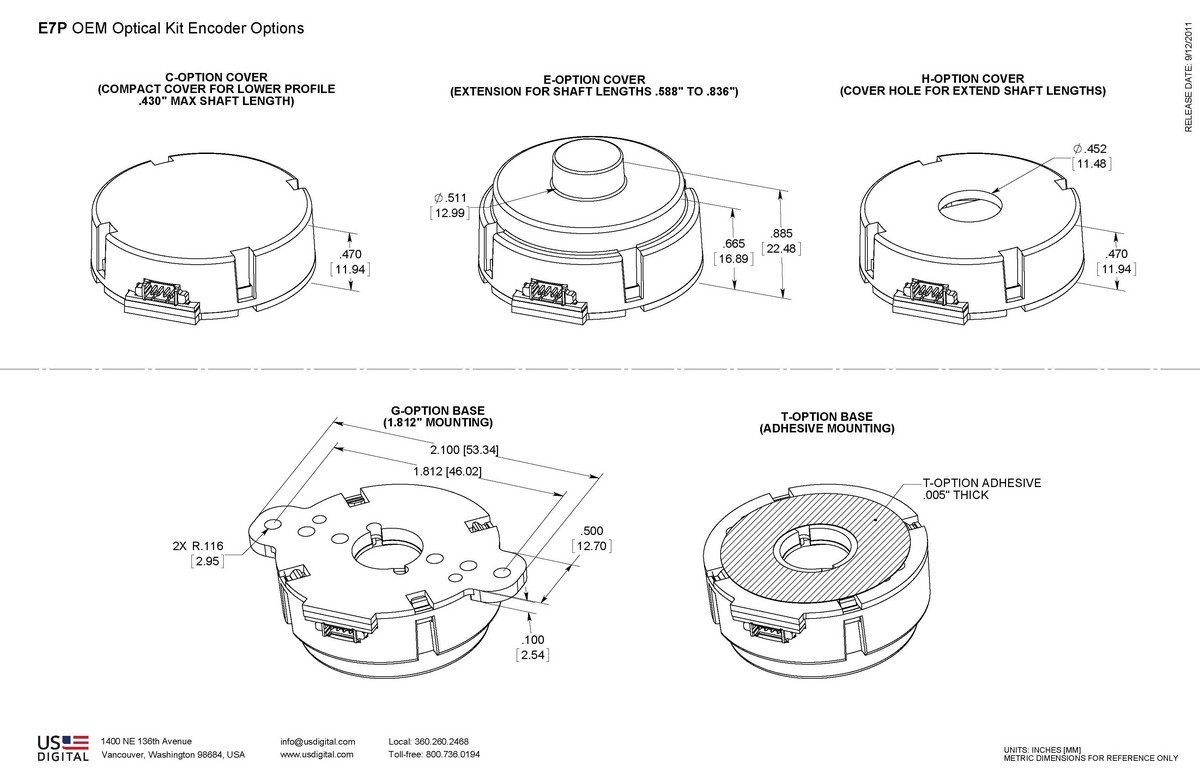

BASE OPTIONS

The set of screws and hex tool included with each encoder depend on the chosen Base option:

| BASE OPTION | BOLT CIRCLE | SCREWS INCLUDED | HEX TOOL INCLUDED |

|---|---|---|---|

| D | 0.750" or 1.280" | low profile #4-40 x 1/4" | .050" hex driver |

| 2 | 1.280" | standard #2-56 x 1/4" | 5/64" hex wrench |

| G | 1.812" | standard #4-40 x 1/4" | 3/32" hex wrench |

| T | n/a | none (.005" thick transfer adhesive with peel away backing mount). | none |

Although standard socket head cap screws will work when mounting the E7P, to maximize clearance between the codewheel and the top of the screw head, we recommend low profile socket head cap screws when using the holes on the E7P board. Both standard and low profile socket head cap screws will work with the G-option.

0.750" Bolt Circle / Low Profile #4-40 x 1/4":

1.280" Bolt Circle / Low Profile #4-40 x 1/4":

1.280" Bolt Circle / #2-56 x 1/4" (2-option):

Provides two #2-56 x " screws in place of two #4-40 x 1/4".

1.812" Bolt Circle / #4-40 x 1/4" (G-option):

Provides mounting ears on the base allowing for a 1.812" bolt circle.

T-option: Transfer adhesive base

The T-option base provides a transfer adhesive

(with peel-off backing) that may be used when

mounting holes are not available. A centering

tool is required when using this option.

COVER OPTIONS

Compact (C-option) provides the lowest profile:

Cover Extension (E-option) provides space in the cover for longer shafts up to 0.836":

Hole in Cover (H-option) provides a 0.452" diameter hole in the cover for shafts:

ACCESSORIES

1. Centering Tool

The centering tool is only included with the -3 packaging option. It has to be ordered separately for other packaging options.

Part #: CTOOL - (Shaft Diameter)

Description: This reusable tool provides a simple method for accurately centering the E7P base to the shaft. A centering tool is highly recommended when using the T-option transfer adhesive.

2. Spacer Tool

A spacer tool is included for all packaging options.

Part #: SPACER-E7P

Description: This reusable tool is used to properly space the codewheel from the encoder.

ASSEMBLY INSTRUCTIONS

PRODUCT CHANGE NOTIFICATION

| Title | Date | Description | Download |

|---|---|---|---|

| EOL - E7P - E8P - PCN 5894 | 02/08/2017 | As part of our on-going product lifecycle management process, we have identified products that will be transitioned to an "End-of-Life" status. Products targeted for end-of-life may be available for a last time buy option prior to being made obsolete, however quantities are limited, and special requirements may apply. | Download |

Notes

- Cables and connectors are not included and must be ordered separately.

- US Digital® warrants its products against defects in materials and workmanship for two years. See complete warranty for details.

Configuration Options |

| E7P |

|

PLEASE NOTE: This chart is for informational use only. Certain product configuration combinations are not available. Visit the E7P product page for pricing and additional information. |