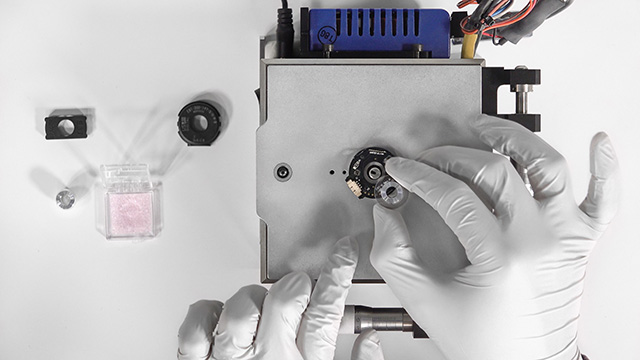

We developed a custom encoder for a customer's medical application

Our MA3’s small size and absolute positioning made it a perfect fit for a handheld human-machine interface. There was only one problem: it was for a surgical application and some of the internal components would prevent the encoder from being properly sterilized.

The customer called asking if we had any similar products that would work in our roadmap, and left the call hearing that we could customize our existing product to meet their needs. Best of all, that process would only take a matter of weeks.

"Design engineers often look for off-the-shelf products that will work in their projects, not realizing that we can offer custom solutions in a relatively short amount of time," US Digital COO Neal Donowitz said. "When we told this medical customer we could develop a custom variant of our MA3 that would meet their needs, they were blown away."

What needed to be changed?

Our MA3 absolute magnetic shaft encoder features a brass housing. That, plus a few internal components were incompatible with applications requiring sterilization.

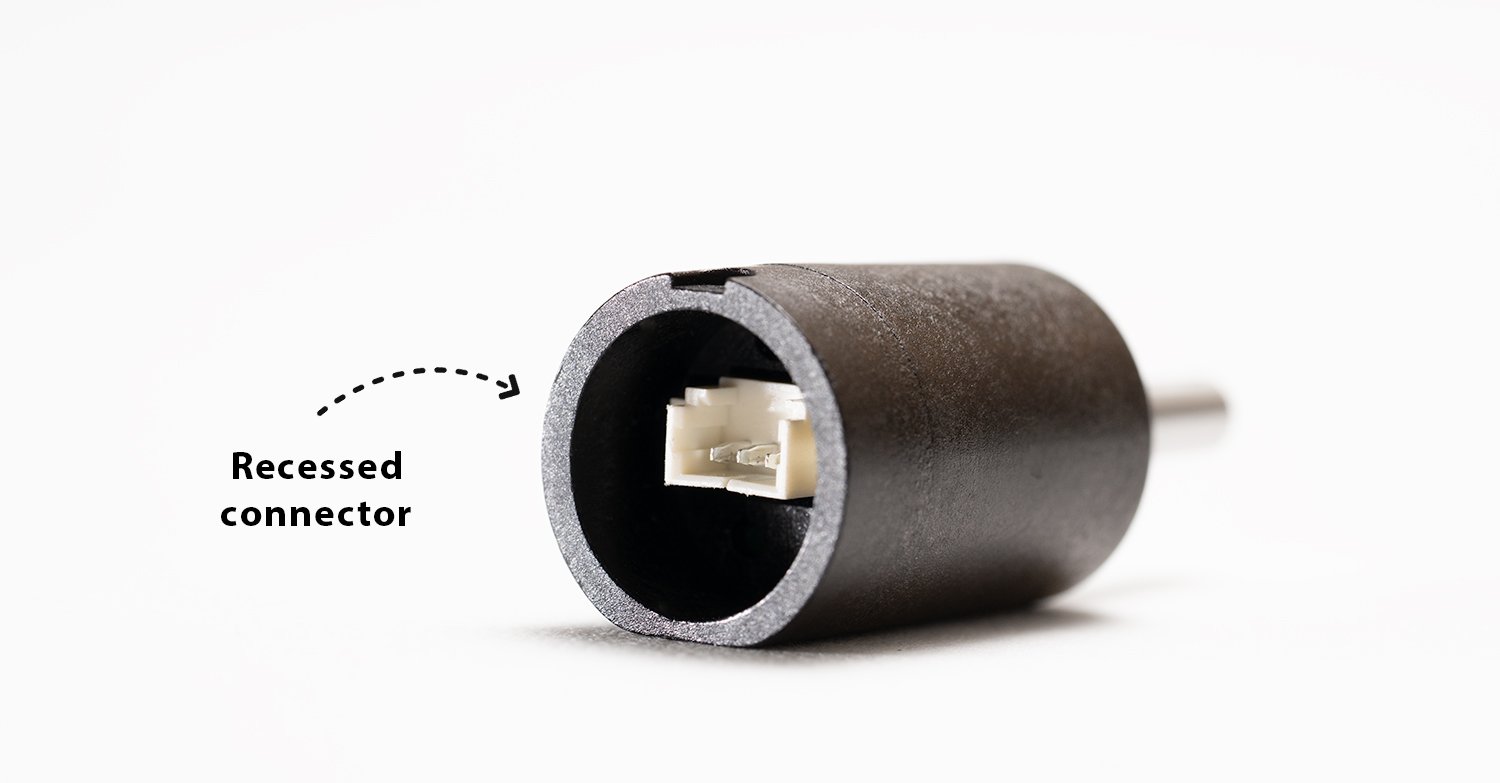

We designed a new, rugged housing that was made of glass-filled polycarbonate that was structurally strong enough for the application. The rear of the housing also featured a pocket so they could encapsulate the connector in place so it wouldn’t get disconnected. We also swapped out bearings for stainless steel ones, so they were appropriate for the application. The new encoder could now be properly sterilized and was better suited for a surgical application.

"We machined parts so they could do trials and make sure our design would meet their needs. Once they were happy with the design, we went into production and that customer used the custom MA3 for more than 10 years," Donowitz said.

Don’t compromise your design

The moral of the story here is that our customer didn’t have to compromise their design or wait months or years to update the design when a new product that fit their needs was released. They called with a problem, and we were able to respond in a matter of weeks.

"If you don’t see what you are looking for in an existing product, don’t hesitate to let us know what you are looking for," said Steve Mathis, US Digital Director of Customer Relations. "We'll do everything we can to help you find a great solution."

While this specific MA3 design is exclusive to our customer, their input on why the stock MA3 didn't work for their application was put into consideration when developing future products, including our S16 shafted encoder. That encoder has a plastic housing, partially because of the input that customer provided on our MA3, Donowitz said.

More in News

Stay up to date

Sign up for our newsletter to stay up to date with our product updates, blog posts, videos and white papers.