Tracking encoder testing, manufacturing details with serial numbers

How much can a series of eight numbers and letters tell you? When it comes to our encoders, it turns out, quite a lot.

We put an eight-digit hexadecimal serial number on every one of our EM1 and EM2 modules, and a seven-digit manufacturer order number on each one of our encoder covers. These numbers allow us to track when individual components were made and keep a record of test results for encoder modules.

Why do we do this? As much as we put an emphasis on making high-quality, reliable encoders, inevitably with any process or procedure issues arise from time to time. We want to be able to quickly respond when they do.

"Problems exist in any manufacturing process and how you address those problems is extremely important," US Digital COO Neal Donowitz said. "One of the details is being able to track things back to the source."

All of us have heard of recalls of everything from foods to cars. If a manufacturer doesn't have a robust tracking system in place, it can be hard to determine the origin of the defect and what batches of products are impacted by the issue.

We excel in being able to identify the when, the where, and the who as to the manufacturing of our encoder components.

Before using serial and manufacturing lot numbers, we could tell you what week of what year your encoder module was manufactured, but we couldn’t get more granular in the details.

That’s not the case anymore.

Encoder manufacturing timeline can be built from MO numbers

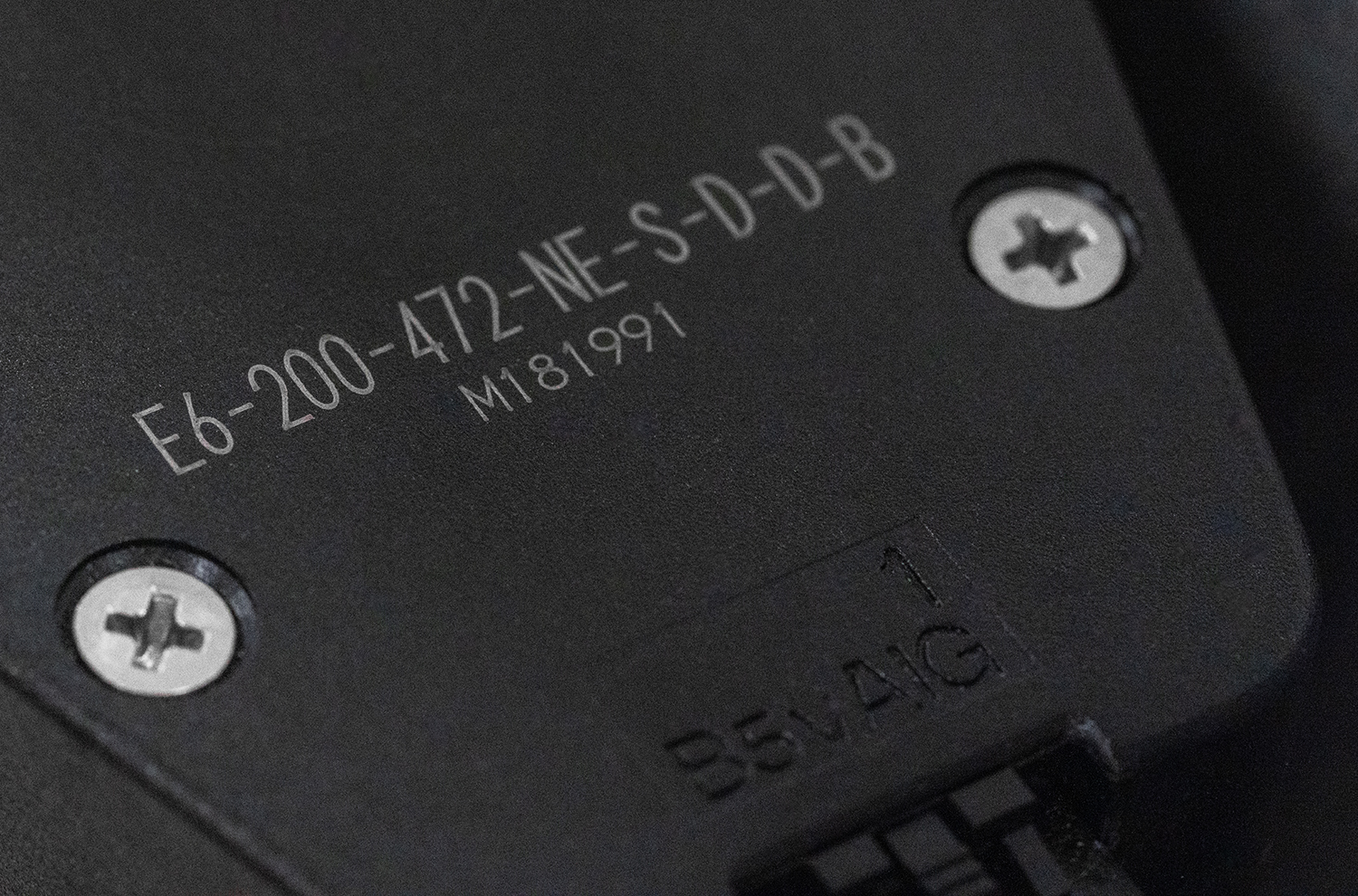

For example, we decided to look into an E6 encoder that is installed on a machine in our assembly department. (The encoder was pre-installed on a linear actuator we purchased for an automation project.) If you look right below the part number, you will see the manufacturing lot number: M181991.

Based on that number, we can tell you we received an order from one of our customers on July 25, 2018—and it shipped the following day. But that is just the start! Here's a timeline when different components of the encoder were manufactured:

2017

November 1 -- The hub was the first component of this encoder to be manufactured.

November 14 -- The spacer tool was produced.

2018

May 1 -- The encoder base was produced.

May 15 -- The lens was produced.

June 25 -- The material used to make the lead frame (which eventually turns into the module) arrives in our warehouse.

July 2 -- The lead frames were over molded.

July 11 -- The cover was produced.

July 23 -- The module was produced along with 1,079 others. (The detector chips that went into these modules came from two wafers — 961 from one and 119 from another -- but who’s counting? The LED chips came from one wafer lot.)

Testing data is tied to module serial numbers

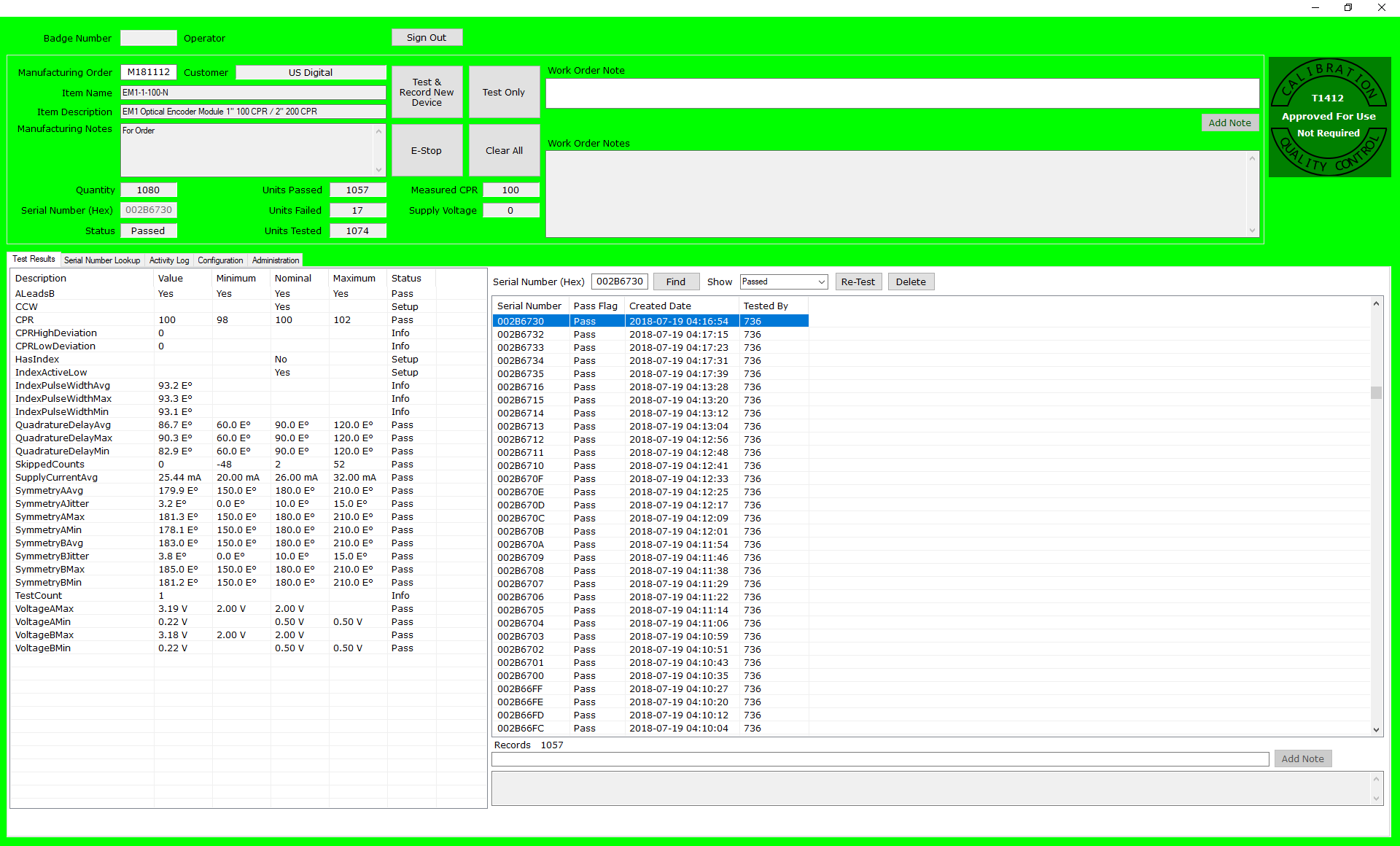

In addition to the timeline, we also have testing data for every encoder module when the manufacturing process is completed.

For example, when we removed the cover from one of the encoders, we found module 002B6730:

Test results for this module can be seen on the left of the image below, with the module serial number highlighted in the column to the right:

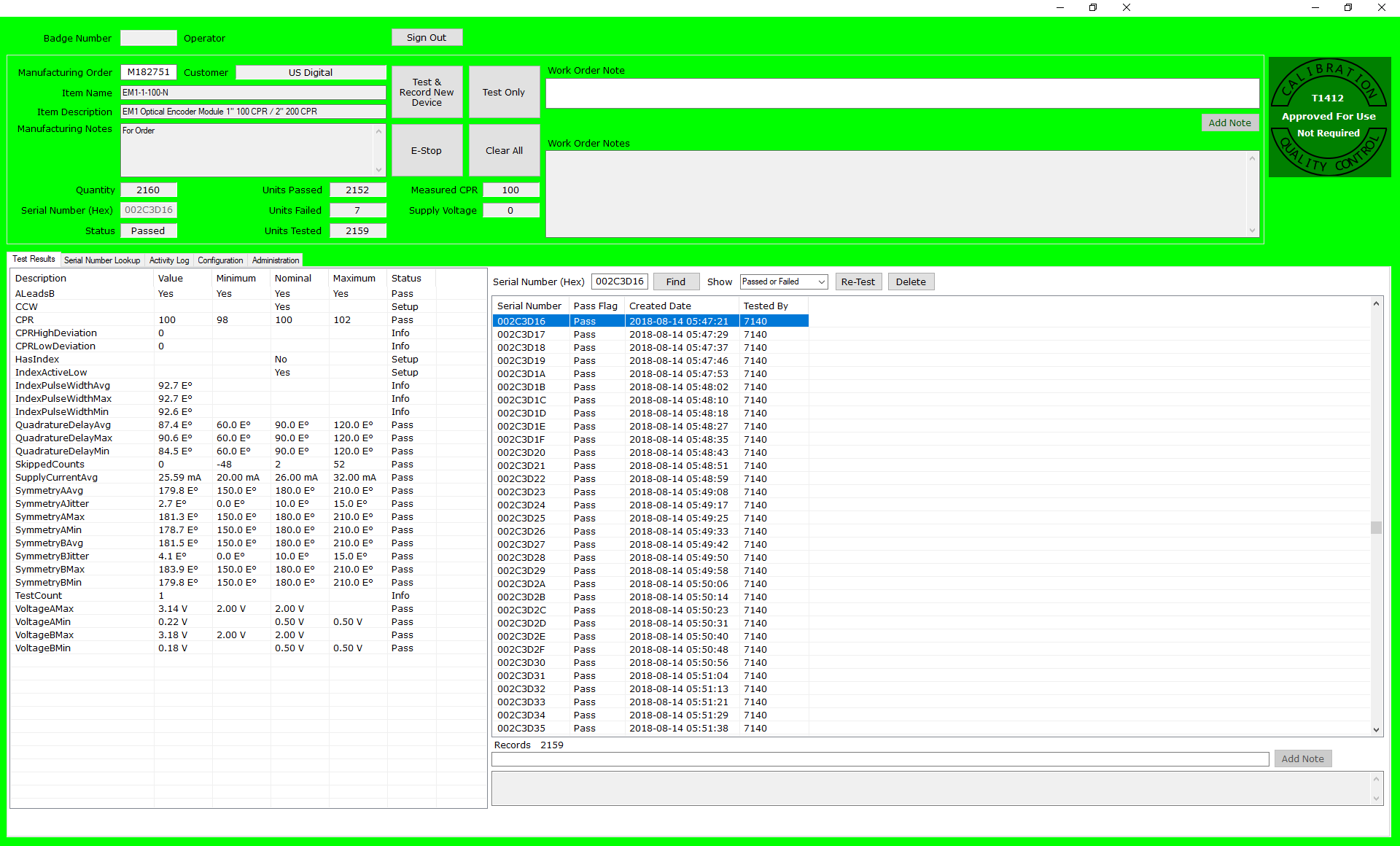

The other encoder module is serial number 002C3D16:

And here is the testing data for that module:

Traceability is important to serving our customers

So this is all great information, but why write a blog post about it?

Whether you're one of our existing customers or someone looking into more information on our company, we thought it was important to emphasize that we're focused on the details. If you have a question about one of our encoders, we want to make sure we're set up the best way possible to answer your question so you can get back to your project.

If you have any further questions or are looking for help with an encoder, be sure to reach out to us and let us know.

Bonus Information

Don’t worry about us running out of serial numbers for the encoders. We typically make about 8 modules per minute—when we’re making them. If you calculate a 40-hour work week (sometimes they volunteer to work longer), we have enough serial numbers to last us well over 4,000 years.

More in News

Stay up to date

Sign up for our newsletter to stay up to date with our product updates, blog posts, videos and white papers.