Encoder mechanical configurations

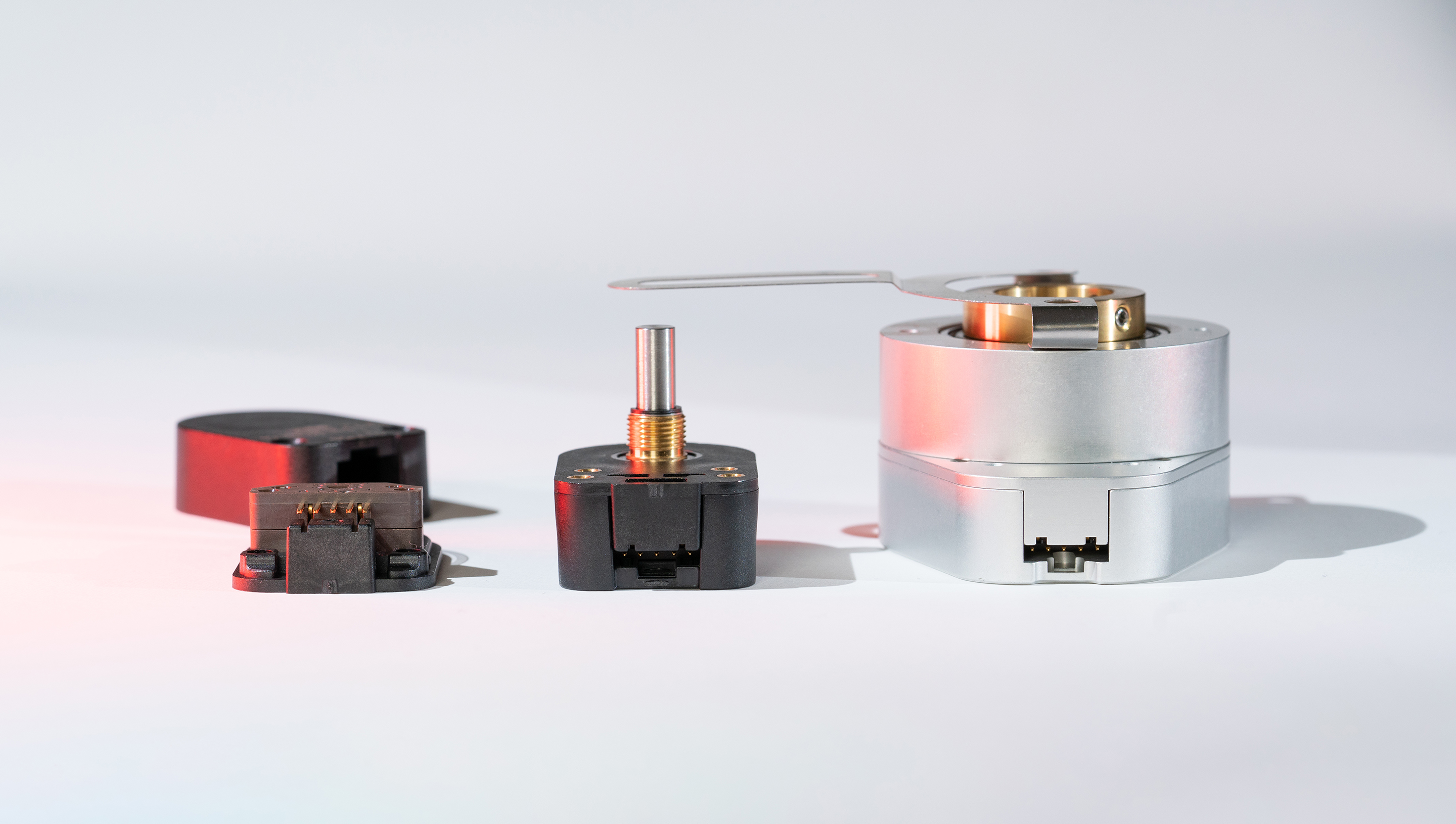

When you're designing a project and need an encoder, one of the most fundamental things you need to figure out is whether your build needs a kit encoder, shaft encoder or hollow bore encoder.

In this post, we'll go over some of the basics of each encoder type and how they can be used. We'll also talk a bit about other physical characteristics, including housing and sensing technology and how those can factor into your build.

Encoders may contain their own bearings, or they may use an existing bearing set for instance: one in the tail shaft of a motor. Encoders with bearings are typically used when the application shaft has a significant amount of axial or radial run out (eccentricity or vibration). The use of a shafted encoder with a motor will require some sort of flexible member, either a flexible shaft coupling or flexible body mount, to allow mechanical compliance with the application shaft operating irregularities.

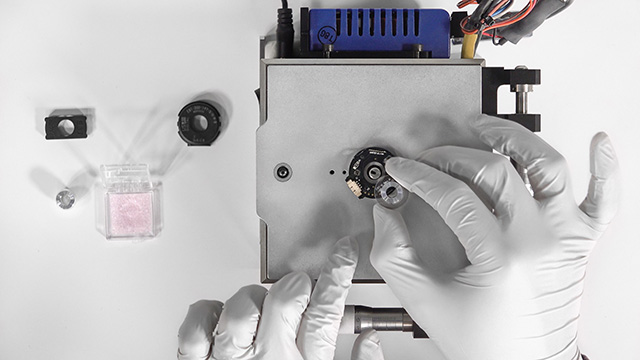

Kit encoders (also known as modular encoders) don’t contain their own internal shaft. They are assembled from components supplied by an encoder manufacturer and are designed to be attached to the tail shaft and end bell of the motor. These encoders rely on a mechanically stable motor shaft, as the shaft is responsible for holding the encoder’s internal rotating code wheel in a precise location relative to the encoder’s sensing module. Because the modular design does not add the expense of the extra set of bearings that a motor feedback encoder does, modular encoders offer one of the most cost effective feedback solutions.

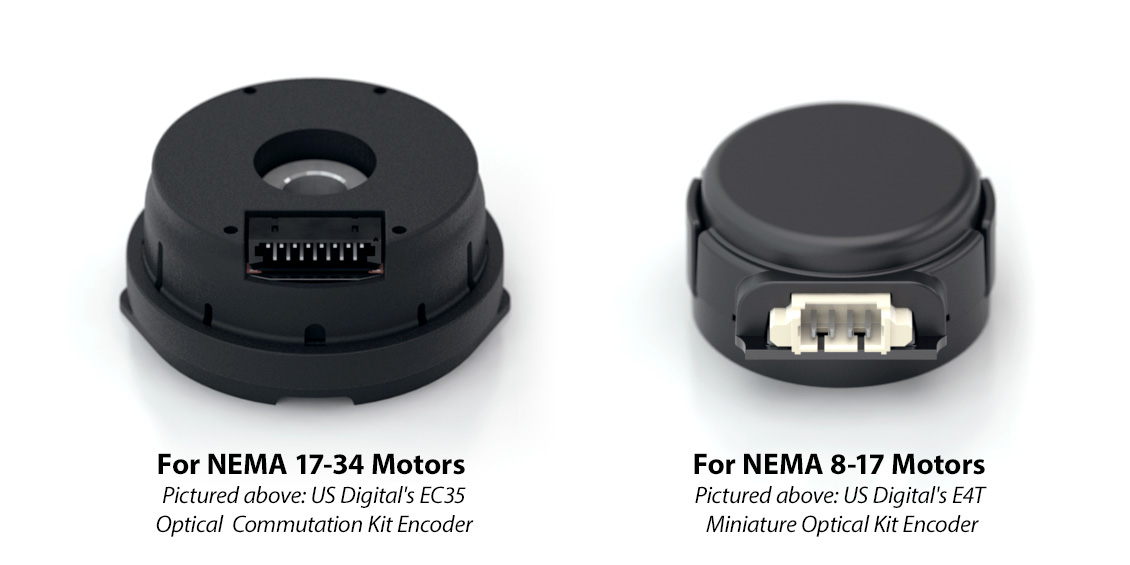

When using a kit style encoder, another mechanical consideration is the size of the motor. Most encoder manufacturers supply a motor/encoder compatibility chart based on the motor size. Be sure to check the encoder's specifications to be sure what size motor -- and shafts -- it supports.

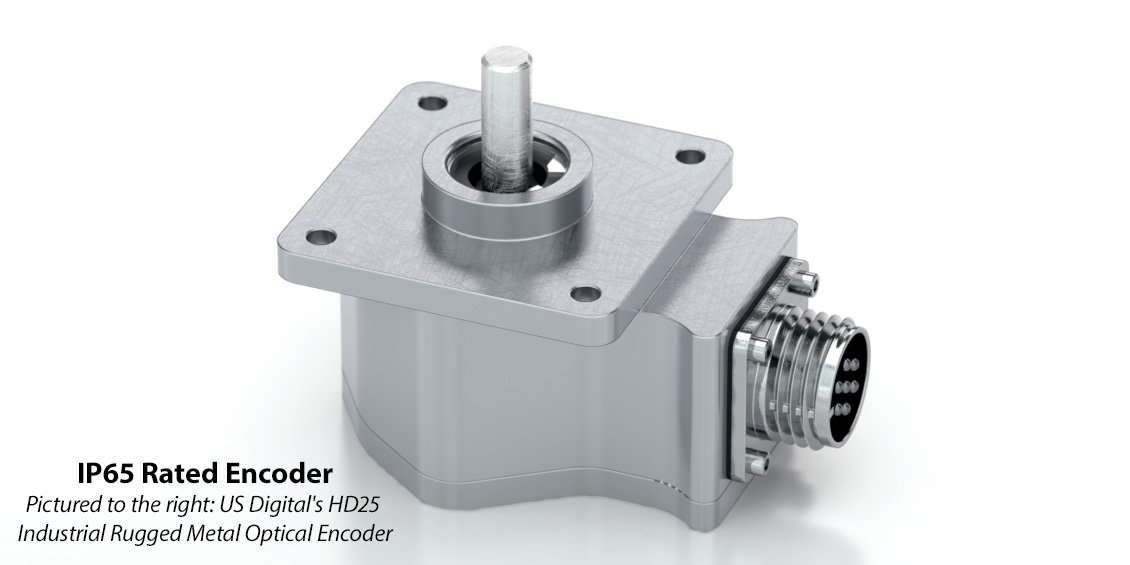

Another mechanical configuration relates to environmental conditions. If the encoder will be installed in an environment that is subject to excessive dust and/or moisture, look for a model with an IP rating or specifications that suits your needs.

Finally, there are many applications where encoders are located where they might require more physical protection than a polymer housing can provide. Some encoders, including our HB5M which is pictured above, has a housing that is machined out of solid aluminum to provide better protection for these type of installations.

More in News

Stay up to date

Sign up for our newsletter to stay up to date with our product updates, blog posts, videos and white papers.