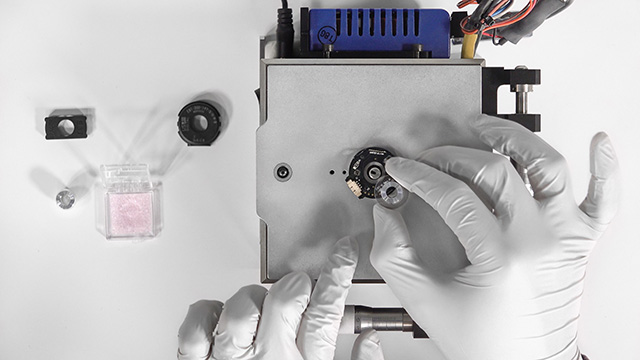

E4 MINIATURE OPTICAL KIT ENCODER

E4 Features

- Minimum shaft length of .285 in.

- Fits shaft diameters of .059 in. to .157 in. (1.5mm to 4mm)

- High retention snap-in polarized connector

- Accepts .020 in. (.5mm) axial shaft play

- Off-axis mounting tolerance of .010 in.

- Tracks from 0 to 60,000 cycles/sec

- 100 to 360 cycles per revolution (CPR)

- 400 to 1,440 pulses per revolution (PPR)

- 2 channel quadrature TTL squarewave outputs

- -20 to +100 C operating temperature

See more info below

Configure the E4